The U.S. Consumer Products Safety

Commission estimates that the likelihood of having a connection

reach

fire hazard condition in a house wired with "old technology" aluminum wiring

(manufactured prior to 1972) is 55 times that of a house wired with copper

wire. There is genuine increased fire risk with such a home and the

homeowner should make modifications to the house wiring system to lessen the

risk.

reach

fire hazard condition in a house wired with "old technology" aluminum wiring

(manufactured prior to 1972) is 55 times that of a house wired with copper

wire. There is genuine increased fire risk with such a home and the

homeowner should make modifications to the house wiring system to lessen the

risk.

It is estimated that there are

approximately 2+ million homes across the U.S. that are "aluminum wired."

These are homes constructed between the years 1964 and 1974.

The problem is not with the wire itself, it is intermittent hot connections

where the wires join together or connect to devices. The reasons for this

can be attributed to the following factors:

1. Aluminum wire has a higher coefficient of expansion than copper and

expands more when current passes through it. This can contribute to

loosening at the connections.

2. Aluminum wire must be slightly thicker than copper to carry the same

loads and this sizing difference may have contributed to loosening connections in early

applications.

difference may have contributed to loosening connections in early

applications.

3. Metals in an oxygen atmosphere oxidize. Copper that oxidizes forms a

conductor while aluminum oxide is a resistor. The resistance at the

connections causes heat to build.

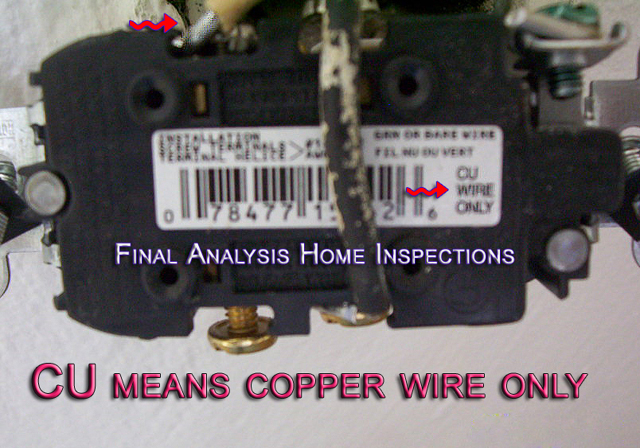

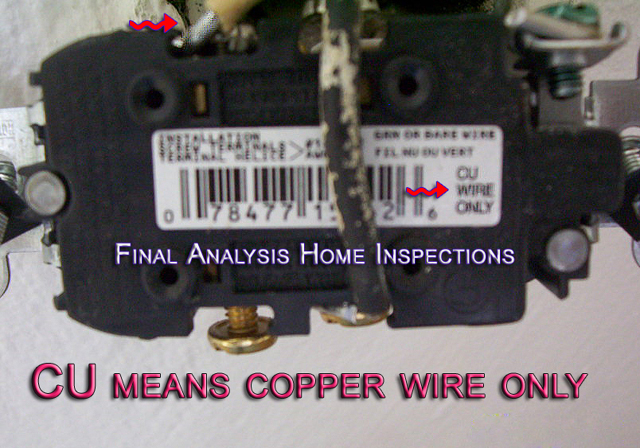

4. Unlike metals which connect can cause an oxide build as well and this

may have caused an increased difficulty when aluminum wire was joined to

devices intended for copper wire. The oxide added resistance.

5. The problem seems to increase as time goes by. This would seem to be

due to increased loosening and oxide build.

Danger Signals: Here are some symptoms that you may have

aluminum wiring in your house or that your aluminum wiring may have

connection problems.

1.

Flickering lights.

1.

Flickering lights.

2. Unusual static on radio or TV.

3. Reduced TV picture size.

4.Arcing or sparks coming from switches or receptacles.

5.Cover plates on switches or plugs hot/warm to the touch.

6. Plugs and lights that don't work. Dead circuits.

7.Circuit breakers that trip for no apparent reason.

8. Arcing sounds within main distribution panels.

9.Melted insulation on conductors near connections.

10. Burning plastic odors near plugs or switches or lighting.

11. Smoke from switches or plugs or junction boxes.

12.Light bulbs that burn out quickly or shine unusually bright.

Making Aluminum Wiring Safer: A variety of modifications have been practiced

over the years but only the "COPALUM" method is considered acceptable by the

U.S. Consumer Products Safety Commission.

US CPSC Pub#516 Repairing

Aluminum Wiring

Warning: Working with older aluminum wire is

more difficult than working with copper wire. An inexperienced electrician

can do more harm than good. Aluminum wiring safety retrofits are best left

to specialists.

reach

fire hazard condition in a house wired with "old technology" aluminum wiring

(manufactured prior to 1972) is 55 times that of a house wired with copper

wire. There is genuine increased fire risk with such a home and the

homeowner should make modifications to the house wiring system to lessen the

risk.

reach

fire hazard condition in a house wired with "old technology" aluminum wiring

(manufactured prior to 1972) is 55 times that of a house wired with copper

wire. There is genuine increased fire risk with such a home and the

homeowner should make modifications to the house wiring system to lessen the

risk.  difference may have contributed to loosening connections in early

applications.

difference may have contributed to loosening connections in early

applications.  1.

Flickering lights.

1.

Flickering lights.